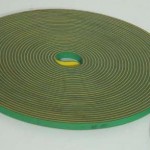

The company is specialized in offering heavy duty Industrial Rubber Conveyor Belts. The Rubber Conveyor Belts supplied by us are fabricated to be used in the industry where bulk material handling is required. These Fabric Reinforced Rubber Conveyor Belts assists in reducing the cost of material conveyed per tone. They are available in varied ranges and width as per the requirements of the clients.

The company is specialized in offering heavy duty Industrial Rubber Conveyor Belts. The Rubber Conveyor Belts supplied by us are fabricated to be used in the industry where bulk material handling is required. These Fabric Reinforced Rubber Conveyor Belts assists in reducing the cost of material conveyed per tone. They are available in varied ranges and width as per the requirements of the clients.

We provide Rubber Belts that are manufactured in accordance to the international quality standards. The General Purpose Conveyor Belts that we present have no alternative available in the market when it comes to high reliability and cost effectiveness.

PVC/Pu Belt Conveyors (as well as Modular Belt Conveyors) are generally used on assembly/packing lines or in clean areas such as the food and pharmaceutical industries.

PVC/Pu Belt Conveyors (as well as Modular Belt Conveyors) are generally used on assembly/packing lines or in clean areas such as the food and pharmaceutical industries.

The traditional PVC/Pu belt conveyor is still widely used due to it being more cost effective than the more modern modular belting, and in instances such as horizontal packing, picking or assembly lines etc, we would generally propose using smooth PVC, or where the belt is in contact with food we would recommend food grade PU.

If an elevation is required we would recommend a grip face rubber belt, although if the angle of inclination exceeds approximately 24 degrees the belt would have to include flights.

Many belts have a woven back which helps grip the end and return rollers, and in addition to this we also supply belts that have tracking strip profiles underneath which folds down over the steel skid base, therefore no tracking is required.

The tangential belt drive is mainly used in the textile industry for driving spindles on ring spinning, open-end spinning, twisting and texturizing machines.

The tangential belt drive is mainly used in the textile industry for driving spindles on ring spinning, open-end spinning, twisting and texturizing machines.

In principle, this is a tangential drive where the power is not transmitted to a single driven pulley but to an array of spindles or rotors. The spindles (rotors) are arranged in a linear manner with the belt pressed against them by pressure rollers to drive them tangentially.

This is why it is referred to as a “tangential belt drive”. Tangential belt drives may have various arrangements, depending on the machine manufacturer, type and size of machines, etc.

Hydraulic seals are a device that restricts the escape of fluid or the entrance of foreign materials in a hydraulic application such as a cylinder. Hydraulic Seals are designed for high pressure dynamic applications such as hydraulic cylinders. Hydraulic Seals are vital in machinery. Hydraulic Seals are critical in producing a way for fluid power to be converted to linear motion. Hydraulic Seals may be used for rotary and reciprocating motion.

Hydraulic seals are a device that restricts the escape of fluid or the entrance of foreign materials in a hydraulic application such as a cylinder. Hydraulic Seals are designed for high pressure dynamic applications such as hydraulic cylinders. Hydraulic Seals are vital in machinery. Hydraulic Seals are critical in producing a way for fluid power to be converted to linear motion. Hydraulic Seals may be used for rotary and reciprocating motion.

Common hydraulic seals include: rod seals, piston seals, symmetrical seals, V-Rings, wipers, rotary shaft seals, wear rings, static seals, back-up rings, o-rings, buffer rings, u-cups, oil & grease seals, cast iron piston rings and gaskets. Hydraulic seals can be single or double acting. Single acting hydraulic seals are used for one axial direction only. Double acting hydraulic seals are used in both directions for a reciprocating motion. Hydraulic seals can be made of a variety of materials: Polyurethane, Nitrile, Viton, PTFE, Silicone, EPDM, POM, Nylon, bronze filled PTFE, Nickel filled PTFE, glass filled PTFE. Some hydraulic seals can be molded of fabric reinforced rubber or leather.

Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction.

Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction.

Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction Introduction.

Oil Seals are used to prevent oil leakage from rotary shaft and housing clearance. It has a flexible lip that rubs against a shaft or housing to prevent leakage or ingress of fluid and dirt. Seal Selection is based on shaft diameter , housing bore diameter and width, shaft speed, working temperature, fluid, pressure differential and service conditions. Common configurations include single lip, double lip, triple lip, and four or more lips.

Oil Seals are used to prevent oil leakage from rotary shaft and housing clearance. It has a flexible lip that rubs against a shaft or housing to prevent leakage or ingress of fluid and dirt. Seal Selection is based on shaft diameter , housing bore diameter and width, shaft speed, working temperature, fluid, pressure differential and service conditions. Common configurations include single lip, double lip, triple lip, and four or more lips.

Rubber sealing element or lip material choices for oil seals include : Nitrile Rubber (NBR), Acrylic Rubber (ACM), Silicon Rubber (VMQ), Fluorocarbon Rubber (Viton/FKM), Ethylene Propylene Rubber (EPDM), Tetrafluoroethylene Resin (PTFE). To resist wear, the compound durometer (hardness) is typically 70 to 85 shore A.

Mechanical seals are being used increasingly on fluid pumps to replace packed glands and lip seals. Pumps with mechanical seals perform more efficiently and generally perform more reliably for extended periods of time.

Mechanical seals are being used increasingly on fluid pumps to replace packed glands and lip seals. Pumps with mechanical seals perform more efficiently and generally perform more reliably for extended periods of time.

Mechanical seals are provided to prevent pumped fluids from leaking out along the drive shafts. The controlled leakage path is between two flat surfaces associated with the rotating shaft and the housing respectively. The leakage path gap varies as the faces are subject to varying external loads which tend to move the faces relative to each other.

The mechanical seal requires a different shaft housing design arrangement compared to that for the other type of seals because the seal is a more complicated arrangement and the mechanical seal does not provide any support to the shaft.

In order for the mechanical seal to perform over an extended time period with low friction the faces are generally hydro dynamically lubricated. The fluid film will need to carry substantial load. if the load becomes too high for the film surface contact will take place with consequent bearing failure. This lubricating film is generally of the order of 6 micrometers thick, or less. This thickness is critical to the required sealing function. Mechanical seals often have one face of a suitable solid lubricant such that the seal can still operate for a period without the fluid film.

The range of O Ring that we offer is immensely popular among our clients. Extensively used in automobile and other industries the range serves varied industrial applications. Further, we offer this array in variety of specifications to meet the variegated client requirements.

The range of O Ring that we offer is immensely popular among our clients. Extensively used in automobile and other industries the range serves varied industrial applications. Further, we offer this array in variety of specifications to meet the variegated client requirements.

‘O’ Rings that we offer is widely acknowledged for its impeccable quality and reliability. These are compressed at the time of assembling of two or more parts, which creates a seal at the interface and assists in proper assembly. Our range is available in varied diameters to meet variegated client requirements. Further, we also provide these ‘O’ Rings in bulk, to meet the rising demands in the market.

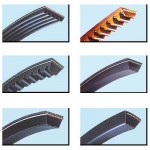

We provide a wide range of Rubber V-Belts in the market. Our Wedge Section V Belts are specially designed for effective performance in inflammable surroundings and also with wide temperature variations. We have incorporated latest technological methods, with strict quality control in the manufacturing process of V-Belts.

We provide a wide range of Rubber V-Belts in the market. Our Wedge Section V Belts are specially designed for effective performance in inflammable surroundings and also with wide temperature variations. We have incorporated latest technological methods, with strict quality control in the manufacturing process of V-Belts.

We offer a complete line of Polyester and Polyurethane V-belts for use in industrial machine transmissions and a wide variety of conveyor applications. V-belts run in single or multiple lines side by side. These belts ensure proper alignment, reduced slippage and are perfect for the transport of products up and down an incline such as boxing, packaging materials, aggregates, glass, tiles and many other products.

The timing belt is a wire rope or glass fiber as a strong layer, covered with polyurethane or neoprene outer annular band, dentate made from the inner periphery of the belt so that it meshes with the toothed pulley.

The timing belt is a wire rope or glass fiber as a strong layer, covered with polyurethane or neoprene outer annular band, dentate made from the inner periphery of the belt so that it meshes with the toothed pulley.

Belt drive transmission ratio is accurate, the axial force small, compact, oil resistance, abrasion resistance, anti-aging properties, the general temperature of -20 ° C to -80 ° C,

Require synchronization transmission is also available in the low-speed transmission.

Belt drive is composed of an inner surface with pitch toothed endless belt and the corresponding fit round the composition. It combines a belt drive, chain drive and gear drive their own advantages. Rotated, is engaged to transmit power through the toothed wheel cogging. Transmission with belt drive the accurate transmission ratio, non-slip, constant speed ratio can be obtained, smooth transmission, absorbing vibration, noise, transmission ratio range, generally up to 1:10. Allow line speeds of up to 50M / S transfer power from a few watts to one hundred kilowatts. High transmission efficiency, generally up to 98%, compact structure, suitable for multi-axis drive, no lubrication, no pollution, it can work normally not allowed pollution and working environment more hostile place. Transmission products are widely used in textiles, machine tools, tobacco, communication cables, light industry, chemical industry, metallurgy, instrumentation, food, mining, petroleum, automotive and other industries for various types of mechanical transmission.